AGE OLD CHALLENGE

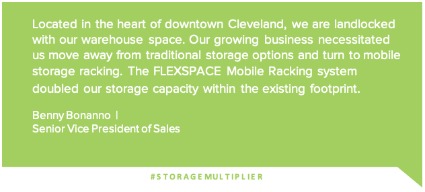

Smith Corona’s growth necessitated a warehouse expansion for additional storage. Its current facility was landlocked which left them no other choice but to utilize real estate across the street. Additional space was achieved at a cost of labor, production, and overhead inefficiencies. A better economical, logistical, efficient solution for increased storage capacity was needed.

Food manufacturers and processors have a long history of seeking out creative solutions that meet consumers’ demands and even create new food categories. One example of creative thinking and “storing more, in less space” is Campbell’s condensed soup. In 1897, Dr. John T. Dorrence, a chemist, invented Campbell’s condensed soup. By eliminating water in canned soup and having the consumer finish the production process, Campbell’s soup was able to lower its packaging, shipping, and storage costs, and made it possible for consumers to buy a can of soup for a dime. Creative thinking with “storing more food in less space” has fed consumers for over 125 years and created sustainable growth and profitability for Campbell’s soup.

The FLEXSPACE Mobile Racking System eliminates static aisle space and creates an automated warehouse storage system. By eliminating the unused aisle space between static racks and replacing it with a single access aisle, mobile racking provides class-leading efficiency, increased productivity, and exponentially increased storage capacity. Win-win: Smith Corona remains in its current facility- in the city they love- while having their storage capacity needs met with the FLEXSPACE Mobile Racking System.

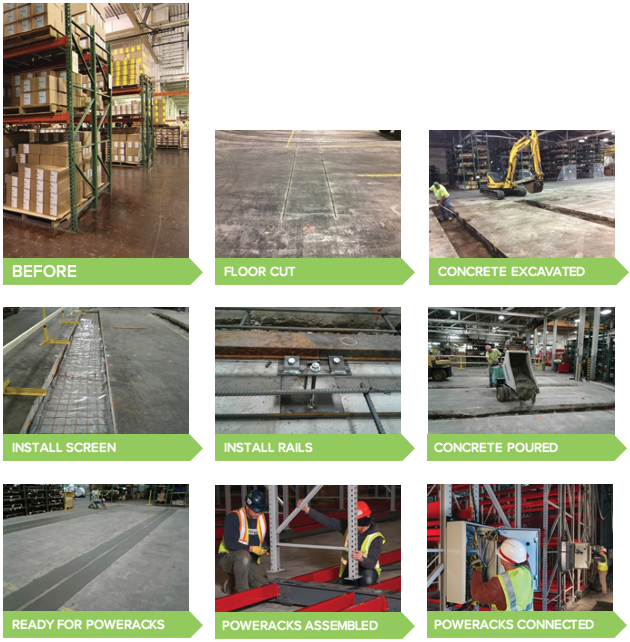

POWERACKS INSTALLATION IN EXISTING WAREHOUSE SPACE

Start to finish, FLEXSPACE Mobile Racking System was installed within four weeks with minimal business interruption. Smith Corona is reaping the benefits of additional storage space within its existing footprint and greater business efficiencies by eliminating leased warehouse space.