Visit FLEXSPACE Booth #1246 to learn how to “make more dough” by increasing storage density within the same building footprint

FLEXSPACE, a leader in revolutionizing food processing and food manufacturers’ storage densification, will showcase its portfolio of high-density automation solutions at the International Dairy Deli and Bakery Association (“IDDBA”) 2023 Exhibition in Anaheim, California, from June 4-6, 2023.

FLEXSPACE will be showcasing the following solutions at IDDBA 2023:

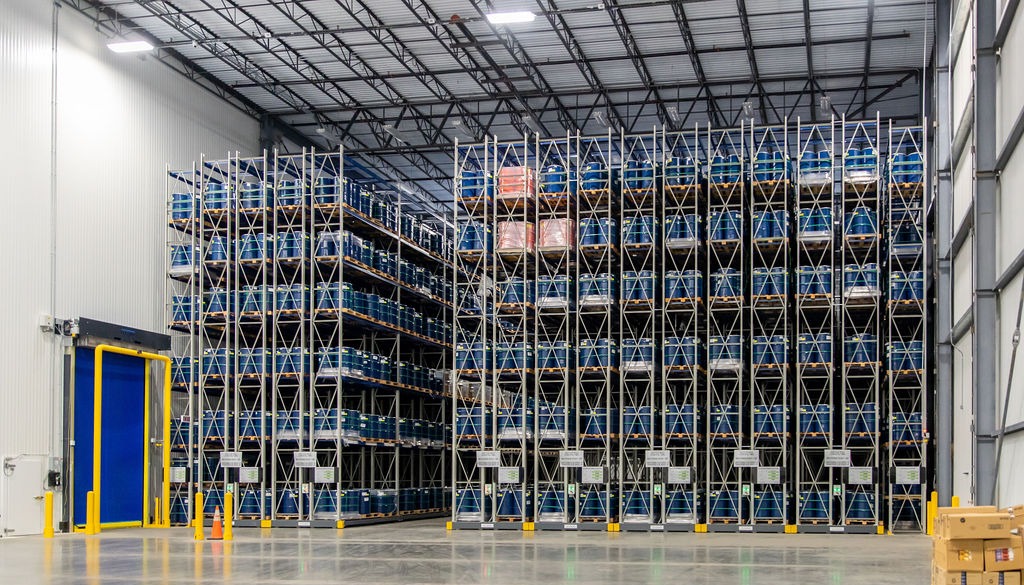

Mobile Racking Systems: FLEXSPACE Mobile Racking Systems have been used for over 50 years throughout Europe and North America. By eliminating aisle space and converting it to revenue-generating storage capacity, more pallets are stored in a smaller building footprint. Direct, unobstructed access to every pallet position increases labor productivity while decreasing overhead, helping to drive higher profits.

The core benefits of the FLEXSPACE Mobile Racking System are:

- Increased storage capacity results from eliminating fixed aisle spaces and converting it to usable storage capacity.

- Single-select accessibility provides visibility to every open and occupied pallet position, eliminating unnecessary pallet movements and ensuring more efficient use of labor and time.

- Less land, less energy, less overhead—by densifying storage capacity, less land is needed to store raw materials and finished goods, reducing energy, lighting, and machinery costs.

- Improved workflows—the mobile racking system can be easily configured to mirror the flow of raw materials and finished goods. This creates a more efficient movement of goods throughout the warehouse and increased labor productivity.

- Flexible rack configuration allows adjustments to accommodate varying pallet sizes, ingredient drums and packaging types.

Pallet Shuttle: FLEXSPACE High-Density Pallet Shuttle is an automated storage and retrieval system that provides maximum storage capacity and efficiency in a variety of warehouse environments. Operated remotely, pallets are placed on the Shuttle using lift trucks. The Shuttle quickly whisks pallets into place within specialized racking tunnels. Pallets can be loaded and unloaded at the front and back of the racking structure, in a First In, First Out (FIFO) or Last In, Last Out (LIFO) system.

FLEXSPACE’s Mobile Racking Systems and Pallet Shuttle reflect our ongoing commitment to innovation in industrial space configuration. By harnessing technology and automation, we help our customers optimize assets and resources to help create a more sustainable and profitable future.

To fully understand the advantages of the FLEXSPACE storage densification solutions, be sure to visit the FLEXSPACE booth #1246 at IDDBA 2023.