Designing your facility for energy conservation

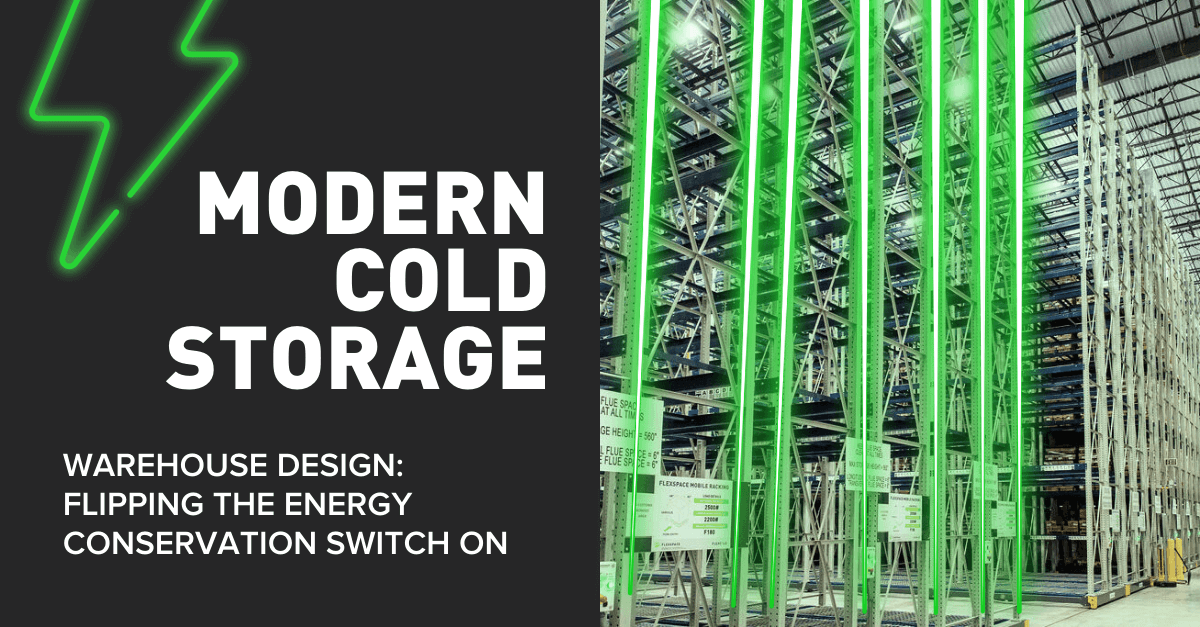

In trying to optimize the energy usage of your operations, we suggest starting at the beginning. The blueprint is the best point to begin your energy conservation culture. Designing and programming your cold storage warehouse for greater storage densification on a smaller facility footprint is an energy and storage capacity win/win.

Including the FLEXSPACE Mobile Racking System at the blueprint stage achieves maximum storage densification on a smaller facility footprint. The ripple effect will impact many aspects of the budget and planning process from the size of the facility, cost to build, future overhead costs, and profitability. By “designing in” the desired density on a smaller footprint, we are immediately creating an efficient, modern, sustainable facility and conserving energy and resources from the get-go.

For example, a traditional double-deep storage warehouse with 29,972 pallet positions would be 154,464 square feet. The same number of pallet positions in a facility using the FLEXSPACE Mobile Racking System would be 106,000 square feet. That’s 32% less square footage. Less square footage points directly to less energy, less equipment that uses energy, and labor that utilizes energy.

The cost of energy in cold storage

Recent studies have suggested that utility costs for cold storage facilities can run from 9% to 18% of revenues, with an average of about 11%. The annual energy intensity of cold storage facilities has averaged 24.9 kilowatt-hours (kWh) of electricity per square foot per year compared to 6.1 (kWh) of electricity per year of a non-refrigerated warehouse. The sources of electricity usage include refrigeration, internal lighting, and equipment motors.

For example, a traditional double-deep storage warehouse with 29,972 pallet positions would be 154,464 square feet. The same number of pallet positions in a facility using the FLEXSPACE Mobile Racking System would be 106,000 square feet. That’s 32% less square footage. Less square footage points directly to less energy, less equipment that uses energy, and labor that utilizes energy.

Refrigeration is the number one user of electricity. Designing for maximum storage density within the most efficient facility footprint means less interior volume to be cooled, less refrigeration equipment, and less energy to run the equipment that cools a smaller space.

FLEXSPACE Mobile Racking Systems = Energy Conservation

In addition, a smaller cold storage warehouse with the FLEXSPACE Mobile Racking System better utilizes space, product accessibility, and organization. Efficient workflows and space usage also equate to less equipment needed, less labor in a smaller space, and reduced energy with lighting, office equipment, and maintenance costs.

The bottom line is, it’s never too early in your planning and design stage to think about energy usage and your storage solution. Let’s talk about how the FLEXSPACE Mobile Racking System can help your organization consume less energy and meet your sustainability goals.

Randy Bates

Chief Development Officer

rbates@flexspace360.com